Pulled out what looked like perfectly good throttle and transmission cables this morning; but don't the cables always look good, until they break.

Taped the new cables to the engineroom end of an old cable and then pulled the old cable out at the helm. It took a little feeding, but the new cables were able to snake along the old cable route. Good thing there are two cables. The first time we tried this technique we pulled the wrong cable, i.e. the one that wasn't attached to a new cable, duh.

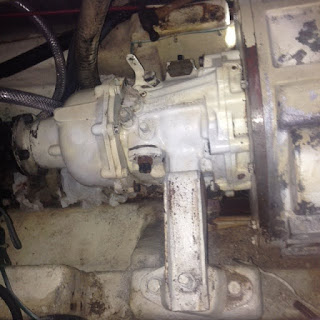

For the record: transmission cable is a Seastar CC33222 and the throttle cable is a Seastar CC33224 (generically 33C 22' and 24' respectively).

Yesterday new insulation was added to the engine room. The forward Racor is being replumbed with 3/8" fuel line with barbed fittings between the Cummins and the Onan. Both the Onan fuel line and the gallery saltwater hose were rerouted under the Onan. The portable water pressure tank, after being degreased, acid etched, primed with POR-15, and painted with Rustoleum white enamel was relocated outboard of the port battery. The bilge under the engine got another coat of Rustoleum gloss white enamel. Put the lift pump on the Cummins and added a 3/8" barbed fitting to its supply side.